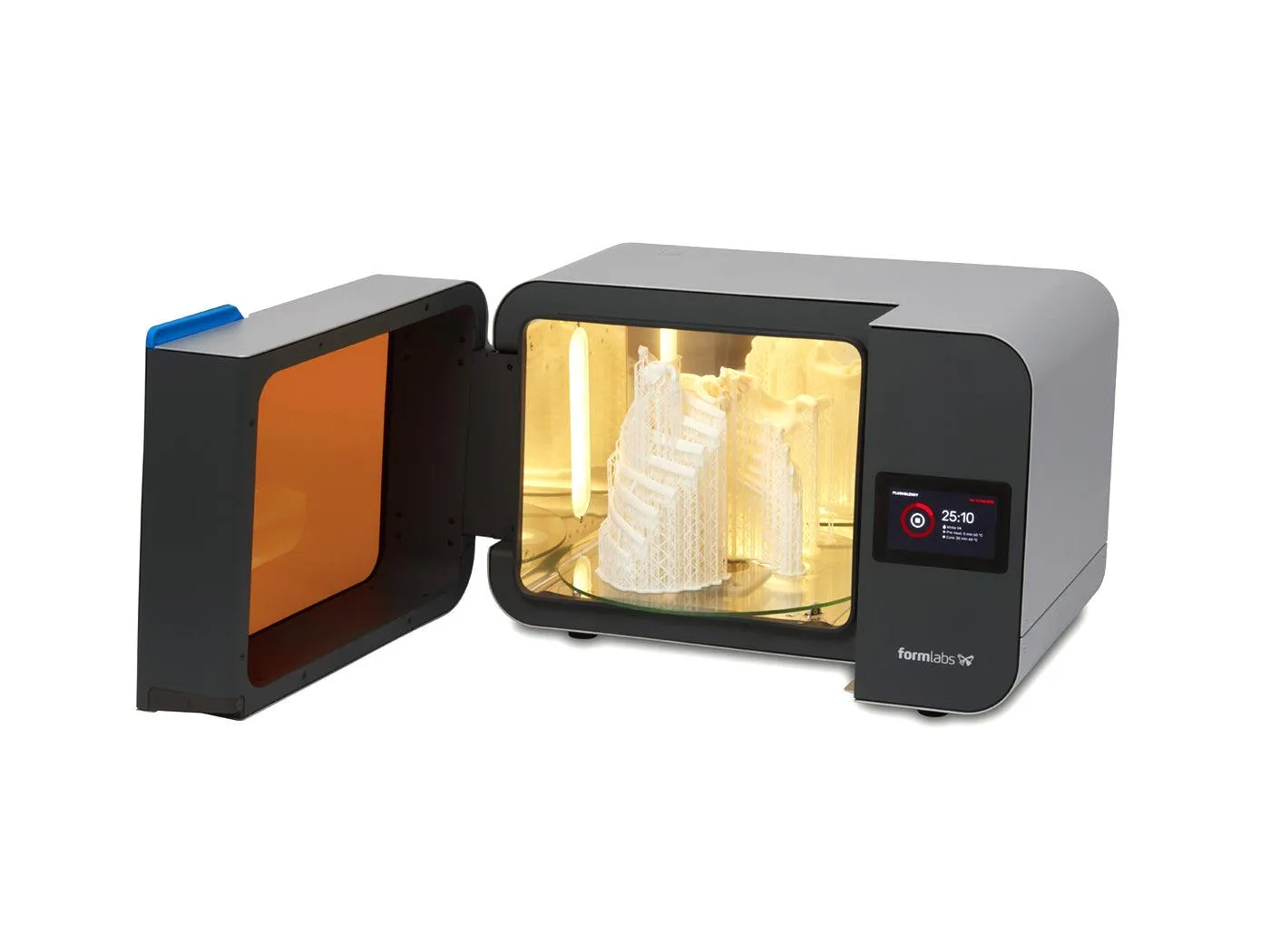

Save time, minimize effort and maximize efficiency with the automated, large format post-processing Form Cure L machine.

The exposes 3D printed parts to the appropriate levels of light and heat to optimize material properties. It uses heat, UV light, and consistent universal exposure to bring parts to their peak mechanical properties and dimensional accuracy.

Optimized for Formlabs Materials - You can use the pre-programmed cure settings or save your own frequently used custom profiles to improve post-processing efficiency.

Rapid, High-Intensity Curing - Two 500W heaters bring temperatures up to 80°C in less than 10 minutes while three UV light modules emit the optimal wavelength of light for fast, effective curing. Once the chamber is heated, 3 LED modules trigger the post-curing reaction, bringing parts to their maximum mechanical properties.

Consistent Universal Exposure - The Form Cure L has a reflective inner cavity and rotating glass turntable that ensure the UV light to reach all the surfaces of the part for a consistent cure.

Form Cure L and Form Wash L have been validated in FDA-cleared workflows and are compatible with biocompatible, sterilizable materials made in the Formlabs ISO 13485 facility.

Specs

Printer Compatibility

- Form 3L, Form 3BL, Form 3, Form 3B, Form 2

Dimensions & Weight

- Dimensions : 69.0 x 54.0 x 44.5 cm (27.2 x 21.3 x 17.5 in)

- Weight : 24kg (53 lb)

- Turntable Diameter : 39.5 cm (15.6 in)

- Maximum Part Height : 32 cm (12.6 in)

Temperatures, Lights, Power & Heater

- Operating Temperature : Suggested 18—28 °C (64—82 °F)

- Maximum Cure Chamber : 80 °C (176 °F)

- Heaters : Dual 500W

- Light Source : 45 multi-directional LEDs

- LED Power : 70W

- LED Wavelength : 375 nm, 405nm

- Power Requirements : Input (NA) 100 - 120 VAC, 50-60Hz, 15A - Input (EU) 220 - 240 VAC, 50-60Hz, 8A

![Axiom 9 - 9" MFD Chartplotter w/Navionics Chart [E70636-00-NAG] Axiom 9 - 9" MFD Chartplotter w/Navionics Chart [E70636-00-NAG]](https://www.smartwindowc.shop/image/axiom-9-9quot-mfd-chartplotter-wnavionics-chart-e70636-00-nag_Bp3V24_285x.webp)